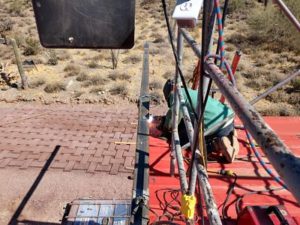

A question I get often is: How do you stay cool working during the summer when temp reach 100+ and often 110+? Answer: I don’t. I get very hot dressed in heavy welding clothes. I sweat a ton! I drink two tons of water. The line on the ground behind me is a garden hose that is on and ready to go (why? see below).

After working this last Sunday I went for a mountain bike in the afternoon at Brown’s Ranch in Scottsdale to cool off. It has many miles of great trails. I had the whole place to myself.

About an hour into my ride I stopped to pickup this saguaro fruit off the ground for a quick tasty snack. As I looked to the northwest I could see a plume of smoke in the vicinity of our home. I called Maggie at home. She went outside and told me the fire was about 1 mile to the west and the air was getting smokey. Raced back to the trailhead and drove back home. Luckily the fire department was able to quickly contain this plumber started fire. A garage and casita burned to the ground. Other recent fires quickly cosumed 1000 acres and destroyed serveral homes.

When welding outside I always thoroughly wet down any nearby vegetation. I do this every 10 minutes to make sure the plants and ground stay wet.